Why Abzena?

Trust our focused approach.

We can develop, optimize and scale-up processes for bioconjugates such as ADCs, AOCs, RDCs and more, providing expert support for both clinical and commercial manufacturing processes.

Our bioconjugate process development approach is defined and designed to ensure scale up directly from bench scale to final manufacturing. By utilizing our deep knowledge of complex chemistry and bioconjugation we rapidly develop and streamline your program development and commercial timelines.

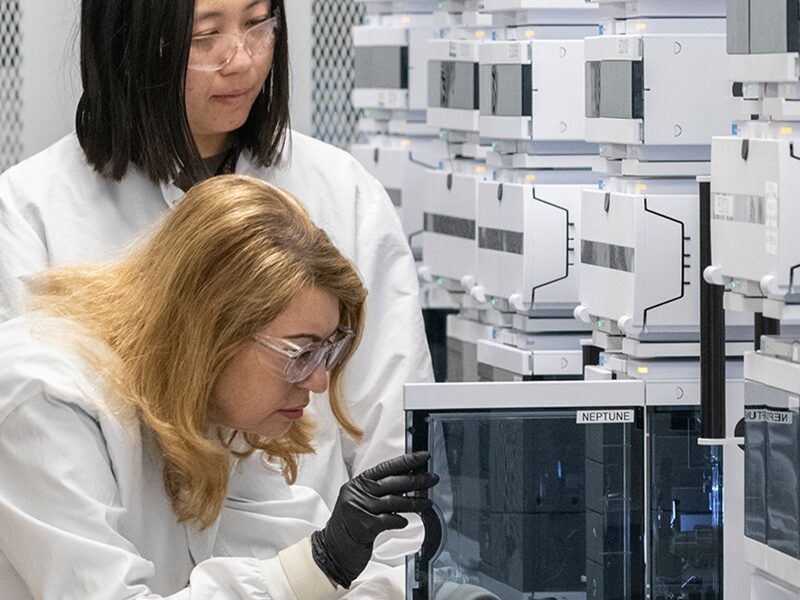

An experienced team of process, analytical and manufacturing experts carry out manufacturing in an upgraded facility with well-established controls (engineering, administrative, and PPE controls) for handling cytotoxic materials.

Our experience goes beyond antibody-drug conjugates (ADCs), including bioconjugates, oligonucleotides, nanoparticles, and vaccines.

Development capabilities include:

Process Development works with Analytical Method Development (AMD) to determine its quality attributes. We design your processes to optimize yields and remove impurities with minimal steps and optimal recovery.

We have years of experience in characterization and supporting the selection of the best candidates for progressing to clinical studies.

Early candidates can be produced from different antibodies, types of linkers and payloads to screen for the most potent solution for your target.

Our process design capabilities include:

Stability indicating assays are identified early on via forced degradation studies performed during process development.

Following completion of stability time point testing, a final stability summary report is provided to support your clinical studies and market authorization applications.

Analytical methods are essential to all aspects of preclinical process development, informing critical decisions and de-risking subsequent development. For the process development of bioconjugates and ADCs we measure drug-to-antibody ratio (DAR), assess conjugation efficiency, determine conjugation site and evaluate product homogeneity through specialized chromatographic methods and advanced mass spectrometry. This data drives process refinements that maintain consistent yields, potency, and overall product safety, supporting a robust and scalable conjugation strategy.

Using a diverse range of expertise in developing and manufacturing ADCs, bioconjugates and linker payloads, we create tailored solutions for your program. We adapt our approach to shorten lead times and develop risk mitigations strategies to ensure your overall success in delivering vital medicines to patients safely.