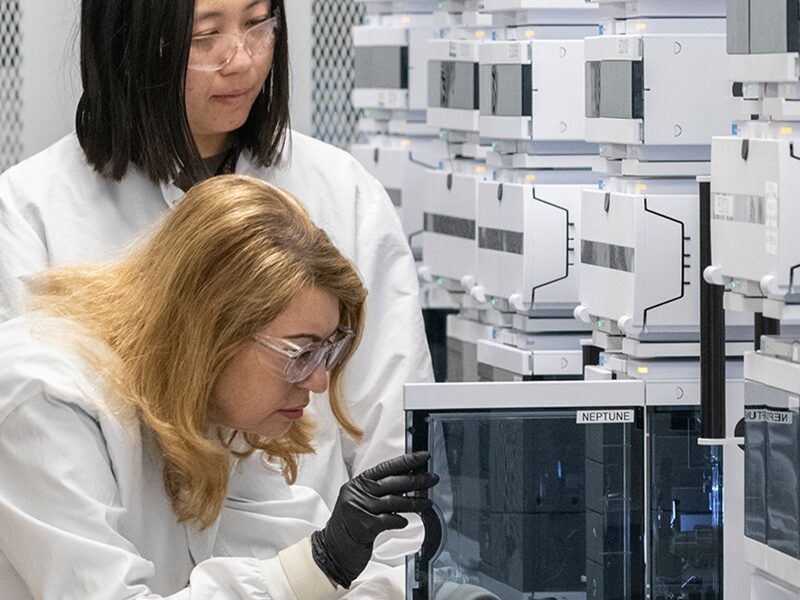

Why Abzena?

Trust our focused approach.

A well designed linker helps the antibody to selectively deliver and release the drug to the tumor site. Our tailored solutions identify and de-risk your clinical candidates for development ensuring stage-specific milestones are met. By applying our expertise in highly potent small molecule process development, we utilize a Design of Experiment (DOE) based approach. Our capabilities include:

We are dedicated to advancing the frontiers of medicine through our specialized linker payload solutions for bioconjugates and ADCs. Our comprehensive suite of services encompasses everything from precise payload design to GMP manufacturing, backed by a deep understanding of monoclonal antibodies and innovative linker technologies.

To accelerate lead drug candidate selection, we apply our knowledge in linker payload design and synthesis, high potency materials, and analytical method development to develop your complex ADCs.

Linker-payload processes are developed and transferred directly to our cGMP manufacturing team minimizing challenges seen during process transfers. We develop the most effective processes for manufacturing at toxicology, clinical, and commercial scale using quality by design (QbD) principles.

Our expert knowledge of cGMP manufacturing enables us to successfully transfer existing processes into our facilities or develop a new innovative process, when needed, to meet your program needs. Processes follow ICH Product Lifecycle guidelines which ensure a robust and well characterized scalable manufacturing process.

Utilizing robust analytics, we ensure the right product quality attributes for your program.

Abzena provides a robust suite of analytical method development services designed to support linker payload design and synthesis. Analytical methods verify the linker’s identity, monitor payload stability, and ensure optimal process conditions during ADC conjugation steps. Our advanced characterization capabilities help confirm the final product and detect potentially harmful impurities or byproducts.

The asset you’re developing right now can make a real difference for human health. Let us apply our wealth of experience to accelerate and maximize its potential.