Why Abzena?

Trust our focused approach.

Through a comprehensive technology transfer program, we deliver a successful scale-up model to ensure robust and consistent bioconjugate manufacturing process from clinical to commercial scale.

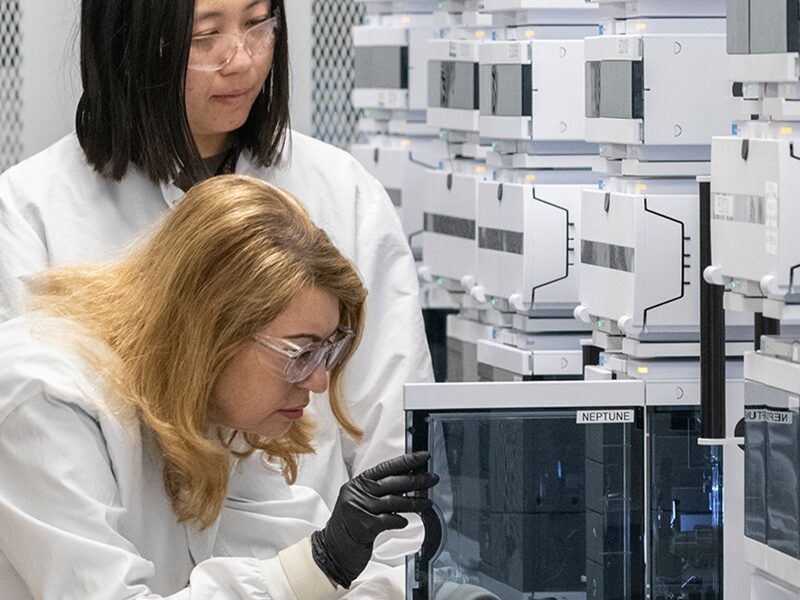

Abzena provides the specialized analytical method support you need, and the technical rigor necessary, for high-quality therapeutics that meet evolving regulatory expectations. Throughout every phase of development and manufacturing, our analytical methods inform critical decisions that de-risk your program.

We are ready to collaborate with your team to de-risk the pathway to commercialization, ensure manufacturability, and deliver a quality medicine to the patient.

Promoting innovation and continuous improvement we adhere to a framework following ICH guidance and work collaboratively alongside you, to support the management of post approval Chemistry and Manufacturing Control (CMC) changes for your product.

Analytical methods are essential to toxicological batch manufacturing, clinical manufacturing, release and stability. Specialized analytical methods monitor product integrity and stability, providing reliable data that informs early-stage development decisions and mitigates risk prior to clinical trials. Abzena’s GMP manufacturing infrastructure uses validated release and stability methods to support clinical trial material production. Routine testing of critical quality attributes (CQAs) ensures each batch meets stringent regulatory standards throughout clinical development.

Abzena has extensive capabilities in cGMP and non-GMP bioconjugate production. We have expertise in employing single-use technology that allows for rapid turnaround times and cost-effective solutions.

Supporting the robust scaling of your project from clinical through to commercial scale, we are dedicated to manufacturing excellence, delivering small molecule intermediates including bioconjugates and antibody-drug conjugates (ADCs).