Why Abzena?

Trust our focused approach.

We ensure compliance with biopharmaceutical regulations for cGMP biologic manufacturing and commercial biologics manufacturing operations. Our dedicated technical teams focus on ensuring your program meets both clinical and commercial goals.

We operate a network of aligned facilities that support biologics commercial manufacturing needs across the lifecycle of your molecule.

By de-risking your program, we ensure technology transfer from your facility to ours, or within our network, is successful and meets all product quality requirements.

Abzena has established a robust, end-to-end manufacturing platform in our San Diego facility that is meticulously designed to produce high-quality biologic drug substance for clinical and commercial use.

By combining a purpose-built cGMP facility, single-use disposable platforms, and rigorously validated processes, Abzena delivers a clear, scalable, and compliant pathway from cell bank to bulk drug substance. Our end-to-end

solution is structured to minimize risk, maximize quality, and help you successfully advance your biologic through clinical development and into the commercial market.

Our modern, single-use facility located in San Diego, CA, deploys the latest in technology and processing, including high titer processing, continuous manufacturing, and perfusion.

Our upstream facilities include Single Use Bioreactors from 50L to 2000L. Our downstream process capabilities include chromatography ranging up to 80cm columns.

We offer industry-leading analytical capabilities such as LC-MS (Orbitrap, QTOF, MALDITOF, QQQ and Q), biolayer interferometry, (u)HPLC, CE, iCIEF and SoloVPE.

Abzena’s Quality organization delivers safe and compliant products to support both clinical and commercial biologics manufacturing programs.

Our Quality organization provides a comprehensive suite of quality services to ensure full compliance with regulatory requirements.

Alongside this expertise, we offer the technologies and analytical capabilities needed to support a wide range of modalities, from straightforward molecules to the most complex.

Below are the key technical elements that ensure both product integrity and operational efficiency at scale:

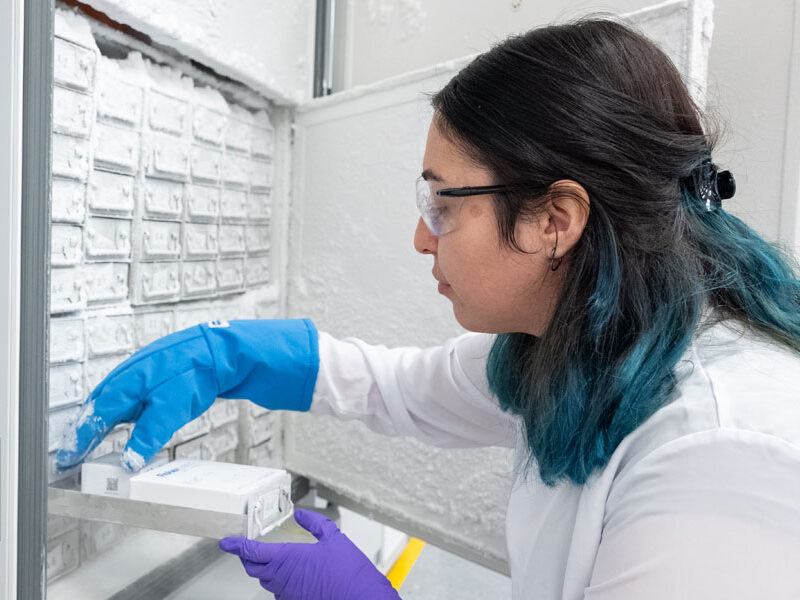

Our San Diego site operates ISO Class 7 and ISO Class 8 manufacturing spaces, with ISO Class 5 biosafety cabinets (BSCs) for critical operations, such as cell bank filling.

We offer parallel manufacturing campaigns within segregated upstream and downstream suites. By allocating dedicated single-use flow paths and product-dedicated purification columns/resins, we mitigate cross-contamination risks and enable flexible scheduling.

Comprehensive quality oversight spans from raw material inspection and weigh-dispense activities, through in-process monitoring and final bulk drug substance release. Our Quality Management System (QMS) integrates documentation, deviation management, change management, and the analytical controls required for both clinical and commercial regulatory standards.

Fluid contact surfaces – including bioreactor bags and downstream tubing—are single-use. This design eliminates the need for cleaning and sterilization validation (CIP/SIP), significantly reducing turnaround times between batches.

Since each batch uses fresh, disposable components, there is no carryover between production runs, ensuring a multiproduct facility can operate without cross-contamination risk or compromising product quality.

Single-use assemblies and a flexible facility design can be swapped out or reconfigured quickly to accommodate new campaigns or scale adjustments, enabling sponsors to move from clinical pilot-scale batches to larger commercial campaigns in a streamlined manner, typically without requirement for engineering runs.

Harvested Cell Culture Fluid (HCCF) is generated through either depth filtration or centrifugation to remove cells and debris. The clarified fluid is filtered through a 0.2 µm filter, reducing bioburden and preparing it for chromatographic purification.

For antibody products, Protein A chromatography is typically used as the first purification step. Eluted material undergoes a low-pH hold to inactivate potential viral contaminants, aligning with global regulatory expectations.

Inline pre-filters and dedicated virus filters provide an additional viral clearance barrier. All process filters must satisfy a post-use integrity test before the resulting material can progress to the next step.

The purified product is concentrated and buffer-exchanged to its final formulation. After a final sterile filtration, the bulk drug substance (BDS) is ready for freezing or direct fill operations.

Production starts by thawing a vial from a GMP Master Cell Bank (MCB.) The culture is carefully expanded over approximately 2–3 passages, moving from shaker flasks (e.g., 125 mL, 250 mL, 1 L) before being transferred into the seed train, typically a Wave RTP (25 L).

Once the initial expansion (N-2 stage) in the Wave bioreactor meets target cell density, it is transferred to a stirred-tank reactor (N-1). Cells are grown for an additional 3 days under optimized conditions – removing selection agents if required – before inoculation into the final production reactor

Operated in fed-batch mode, the production vessel is monitored for pH, dissolved oxygen, and temperature. Precise feed strategies and agitation profiles maximize cell viability and product titer. Upon reaching the desired endpoint, the culture is cooled and prepared for harvest.

Commercial biologics manufacturing involves producing biologic therapies at the scale, quality, and consistency required for global commercial supply.

Abzena provides cGMP facilities, advanced single-use systems, and technical expertise to deliver reliable clinical through commercial biologics manufacturing programs.

Our facility uses high-titer processing, continuous manufacturing, perfusion, and scalable upstream and downstream systems suited for commercial supply.

Abzena’s Quality organization provides end-to-end oversight to ensure all products meet regulatory standards and commercial release criteria.

With all manufacturing phases – from cell expansion through final drug substance – consolidated under one roof, Abzena is well-equipped to support your program’s journey toward successful clinical outcomes and reliable commercial supply. Interested in learning more about our fully integrated development and manufacturing capabilities for biologics?