Why Abzena?

Trust our focused approach.

We select your best lead candidate through screening of optimal buffer conditions and formulation options to inform successful drug substance manufacturing conditions and drug product forms that support long-term stability.

Our team is experienced in developing formulations for small and large therapeutic molecules such as peptides, proteins, monoclonal antibodies and antibody-drug conjugates (ADCs).

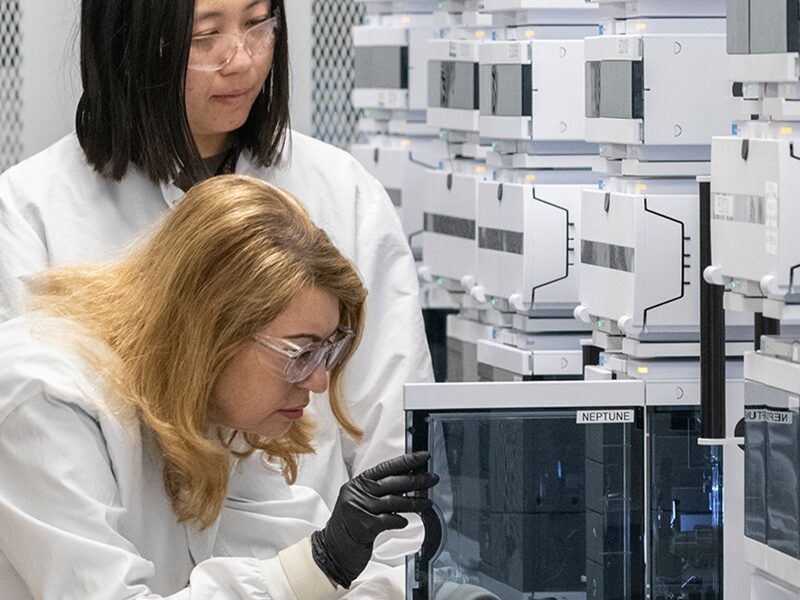

We have the latest analytical equipment and methods to evaluate the integrity of your drug under an array of conditions to inform optimal formulation constituents and forms.

Our capabilities include:

Abzena puts into play a flexible and customizable approach to achieving your bioconjugates target product profile (TPP). With timelines always in mind, Abzena applies practical and phase-appropriate processes with early-stage (pre-Phase I) formulation activities focused on rapid progression to IND – “fast to clinic,” whilst later-stage formulation activities are focused on providing the best

product – “best in clinic.”

Extended thermal stability of the final formulation assessed in the final format i.e. pre-filled syringes, cartridges, plastic/glass vials, etc

Abzena provides a robust suite of analytical method development services designed to support bioconjugate formulation development. These analytical methods inform critical decisions and de-risk subsequent development phases. Through stress testing, forced degradation studies, and excipient compatibility assays, we identify optimal formulation conditions to maintain stability, extend shelf life, and that are appropriate for the desired route of administration. Particle size analysis and charge variant profiling further confirm that the product remains within defined quality attributes.

We also produce toxicology-ready batches under controlled conditions to support pre-clinical studies, ensuring consistent product characterization and safety.

Bioconjugate drug formulation is the process of combining different chemicals and substances to create a final biopharmaceutical product. The formulation process is not just about creating a drug that works; it’s about ensuring the drug reaches those who need it most – in a form that maximizes its therapeutic potential.

Solubility and stability are key factors; poorly soluble bioconjugate drugs can lead to reduced bioavailability, making them ineffective. Stability is crucial to maintain the drug’s efficacy over time, with methods like lyophilization or freeze drying used to preserve the drug under various conditions.

The rise of personalized medicine through an ever-increasing range of bioconjugate modalities means that formulation development must cater to specific patient needs. Through focusing on individual patient profiles, including age, health condition, and preferences, formulation scientists are developing more effective, and patient-friendly medicines.

The treatments you’re developing right now can make a real difference for human health. We can work together to ensure your success, combining our deep scientific and technical know-how with your promising asset.