Leadership Team

Meet our experienced team.

From process development to analytics & bioassays, and cGMP manufacturing, our experienced teams deliver high-quality programs that help our customers get life-changing medicines to patients faster.

Watch our video below to learn more about our trio of facilities in San Diego, CA, USA.

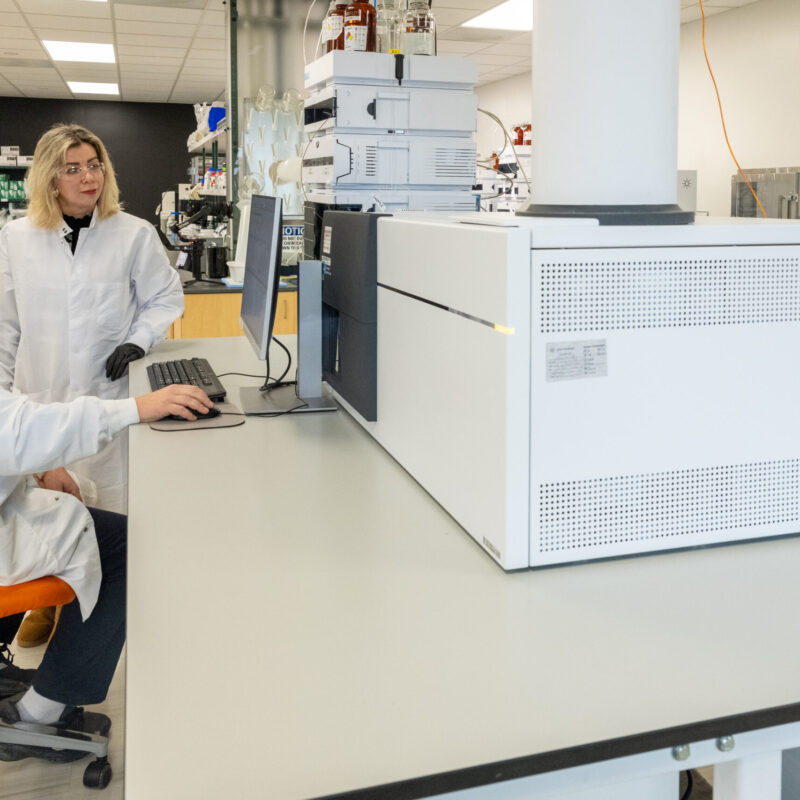

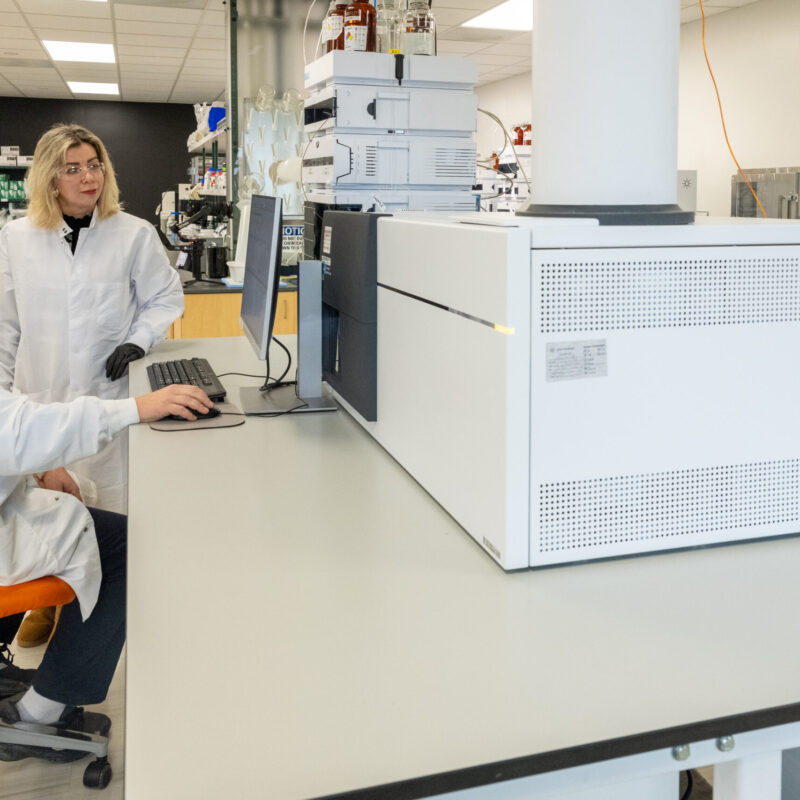

Our knowledgeable and dedicated team of scientists develop analytical test methods and qualification protocols to ensure the production of high-quality, and well-characterized material, in order to generate the data needed to support successful IND, IMPD and marketing applications.

The state-of-the-art, built-for-purpose, GMP manufacturing facility has the production capacity to scale your program from 50L to 2000 L. Using the same equipment families from bench processes, and leveraging single-use technologies, we can ensure an expedited path to the clinic.

Key manufacturing features:

QC analytical and microbiology laboratories are fully equipped to provide the comprehensive QC support needed to safeguard your program including release testing, Certificate of Analysis Generation, stability program management and raw material and in-process testing.

Our 22,000 sq ft GMP warehouse has 3 walk-in freezers and a continuous temperature monitoring system to ensure your product is appropriately stored. Each package is inventoried using our electronic inventory management system, where raw materials are quarantined, released, and stored at their necessary requirements.

When it comes time to transfer your program to a downstream supply chain partner, our program managers work as an extension of your team to ensure on-time delivery, so that your project timelines and goals are always met.